A fruit that is loved by all

Juicy Delights: Our Exquisite Grapes

Natural freshness – We maintain natural freshness in all the processes, starting from the orchard until it delivers.

Large Farmers base – we are associated with more than 500 Global GAP-certified grape growers. We strongly believe that we as an organis

ation could only grow when our growers prosper.

Farm to fork Traceability – We maintain total transparency and traceability in all the processes from farm to fork that is from harvesting, packaging, Logistics and delivery.

Trust and transparency – We maintain full transparency in every aspects of our business, whether it is our fruit, or services.

Food Safety and Hygiene – We follow all the globally accepted and followed food safety and hygiene norms, including at our farms, logistics and packing.

Sustainability – We ensure good agricultural practices, supply efficiency, quality production, efficient logistics and affordable price, all in an environment-friendly manner.

Efficiency – Our long-term industry experience in harvesting, Post-harvest treatments, Cold supply chain and efficient logistics ensure that our fruits are harvested fresh, shipped fresh, and ready to eat fresh, always.

With our long-time experience in Indian fruit export, our vision is to spread Indian fruits along with Indian Culture to every part of the world.

Quality and safety tested

Zero Waste Output

Top Notch Fruit Care

Our Farm to Packhouse Operations

–

– We’ve exported over 4 lakh boxes or 20 lakh kgs of grapes

– Expanded our market to Europe, U.K., Russia, Taiwan, Thailand, and Saudi Arabia!

Grape Plantation at our Farms

We carefully grow our fresh produce with careful soil testing, use of organic fertilizers and utmost fruit care to bring you Trident’s fresh produce from farm to table.

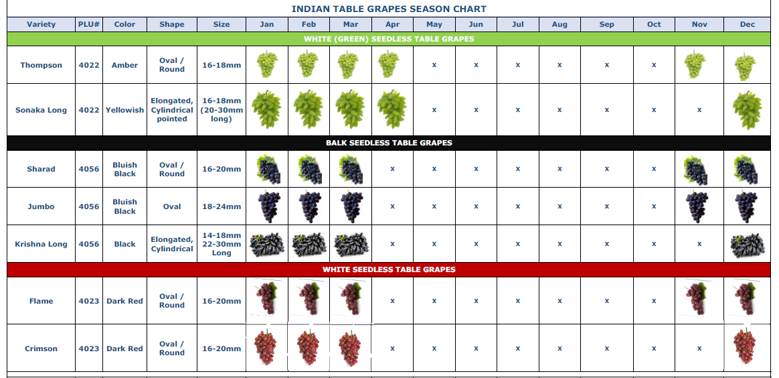

1. White Seedless Varieties

Thompson Seedless (Brix: 16)

Colour: Milky green

Size: 16mm to 18mm

Shape: Oval

Manik Chaman Seedless (Brix: 16+)

Colour: Light milky green

Size: 18mm to 20mm

Shape: Oval

Sonaka Elongated Seedless (Brix: 16+ )

Colour: Light green

Size: 14mm diam, 22mm length

Shape: Elongated

2. Black Seedless Varieties

Sharad Seedless (Brix: 16+)

Colour: Dark Red/Black

Size: 16mm to 18mm

Shape: Round

Jumbo Seedless (Brix: 16+)

Colour: Black to purple

Size: 20mm to 24mm

Shape: Oval

Krishna Long Seedless (Brix: 16+)

Colour: Black

Size: 14mm diam, 22mm length

Shape: Cylindrical

3. Red Seedless Varieties

Flame Seedless

Colour: Light Red

Size: 16mm to 18mm

Shape: Round

(Brix: 16+)

Crimson Seedless

Colour: Milky Red

Size: 16mm to 18mm

Shape: Round

(Brix: 16+)

Grapes Plantation at our Farms

Grapes are grown in more than 150 countries, and 105 million tonnes of fruit are produced each year. The production of grapes is a long process of three different stages – the vegetative stage, the flowering stage, and the fruiting stage.

1. Site Selection and Preparation

Climate: Grapevines thrive in temperate climates with well-defined seasons, including warm summers and cold winters.

Soil: Well-drained soil is crucial. Grapevines prefer slightly acidic to neutral soil (pH 6.0-7.0).

Land Preparation: The land is cleared of weeds and debris. Soil is often tested and amended with organic matter or nutrients as needed. Soil is then tilled to improve drainage and aeration.

2. Choosing and Planting Varieties

Variety Selection: Choose grape varieties based on climate, soil type, and market demand. Common varieties for export include table grapes like Thompson Seedless and Crimson Seedless.

Planting: Grapevines are typically planted during the dormant season (fall or early spring). Planting involves spacing vines adequately (usually 6-8 feet apart) to allow for growth and air circulation.

3. Vine Training and Trellising

Trellising Systems: Grapevines need support, which is provided by trellising systems. Common systems include vertical shoot positioning (VSP) and Geneva Double Curtain (GDC).

Training: Vines are trained to grow along the trellis to optimize sunlight exposure and airflow. Training methods vary depending on the system used.

4. Maintenance and Care

Watering: Grapevines require regular watering, especially during dry periods. Drip irrigation is commonly used to provide consistent moisture.

Fertilizing: Grapevines are fed with fertilizers to ensure healthy growth and fruit development. The type and amount of fertilizer depend on soil fertility and vine needs.

Pruning: Pruning is essential for managing vine growth and improving fruit quality. It is typically done during the dormant season. Pruning helps in controlling the number of grape clusters and improving air circulation.

Pest and Disease Management: Regular monitoring for pests (e.g., grapevine moths) and diseases (e.g., powdery mildew) is crucial. Integrated pest management (IPM) practices are used to control and prevent issues.

5. Fruit Development

Flowering and Fruiting: Grapevines flower in late spring to early summer. Pollination is typically wind-assisted or done by insects.

Berry Growth: After flowering, berries develop and grow. They undergo veraison, where they start changing color and ripening.

6. Harvesting

Timing: Grapes are harvested when they reach the desired sugar content (brix level), acidity, and flavor profile. This timing varies depending on the grape variety and intended market.

Methods: Harvesting is often done by hand to avoid damaging the delicate fruit, though mechanical harvesters are used in some regions. Grapes are carefully cut from the vine and placed into containers.

7. Post-Harvest Handling

Sorting and Cleaning: Grapes are sorted to remove any damaged or unripe fruit. They are also cleaned to remove any dirt or debris.

Cooling: Grapes are cooled quickly to preserve freshness and extend shelf life. This is usually done using refrigerated rooms or cooling tunnels.

Packaging: Grapes are packed in containers designed for export, such as clamshells or cartons. Packaging must protect the grapes and ensure they remain in good condition during transit.

8. Quality Control

Inspection: Grapes are inspected for quality and compliance with export standards. This includes checking for size, color, and any signs of disease or damage.

Certification: In many cases, grapes must meet specific phytosanitary and quality certifications required by importing countries.

9. Export Logistics

Documentation: Necessary export documentation is prepared, including certificates of origin, phytosanitary certificates, and any required customs forms.

Transport: Grapes are transported to their destination using refrigerated shipping methods (such as containers with temperature control) to maintain freshness.

Distribution: Upon arrival, grapes are distributed to various markets and retailers.

Hallmark of Quality

Our certifications include Global GAP, GRASP, BRC and SMETA

More than the taste, grapes which are also known as 'Vitis vinifera' are natural antioxidants and a great source of resveratrol which protects from stress; and has anti-ageing and anti-inflammatory properties. Table grapes have a lower sugar content than wine grapes.

We are the ONLY company in India with a ZERO WASTE OUTPUT management system.

Our Grapes Specifications

We started our Grapes Exports in 2022. Each piece of grapes contains:

Nutrient Information

Calories – 104

Fibre – 1.4 g

Carbohydrates - 27.3 g

Protein - 1.1 gm

Vitamin - K

Minerals - Calcium, Magnesium, Potassium, Phosphorus, Manganese

The availability season for Grapes is primarily from November to April.

Type of Packing Available - We Offer Paper Bag Packing, Punnet Packing and Plastic Packing

Our grapes are sourced from the picturesque farms of Maharashtra’s Nashik and Sangli districts known for their finest grapes. We work with 10,000 farmers in this grape capital of India to bring you the most nutritious and fresh grape varieties.

We export approximately 1.5 million tonnes of grapes annually to markets across Europe, the UK, Asia, the Middle East, and South Asia. Our focus is on delivering premium-quality grapes with lower residue levels at competitive prices.

Growth Stages of our Grapes

Budburst

Early Shoot and Leaf Growth

Flowering and Fruit Set

Version and Berry Ripening

Winter Dormacy

Labelling and Packaging

Packhouse

Cold Storage

Some Facts That Are Hard to Grapple with!

Make a Fruitful association today!

Still have questions ?

Can’t find the answer you’re looking for? Please chat to our friendly team.